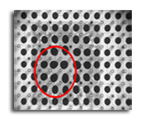

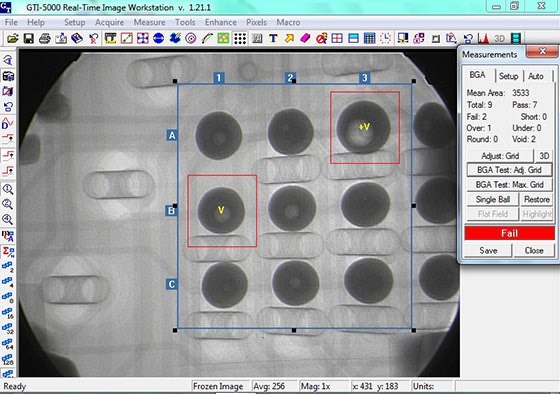

BGA/SMT Inspection

Precision Images for Advanced Assembly

Glenbrook offers real-time x-ray technology to evaluate solder joint integrity for BGAs and other leadless packages that cannot be inspected by conventional vision systems. And Glenbrook’s patented x-ray camera offers a unique advantage: it is the only system not subject to Voltage Blooming. In addition, void sizes remain consistent at all voltages, providing reliable pass/fail data.

BGA analysis helps to establish and maintain quality as an integral part of process control at every stage of your line. And Glenbrook patented X-ray systems may ensure that those quality parameters are being maintained at those stages and also during production audits.

A Family of X-ray Inspection Systems Providing Affordable Choices for Inspection of BGAs and Electronic Assemblies

RTX-113HV (3500 Series)

Low Cost X-ray Inspection of Bare Boards and Plastic BGAs

Ideal for inspection of multi-layer and assembled PC boards. Whether in your drill room for inspecting multi-layer PC boards or your SMT Production Floor for inspecting assembled boards, the RTX-113HV (3500 Series) is a user friendly, high performance x-ray machine with unsurpassed reliability.

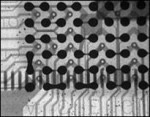

JewelBox-70T™

High Magnification X-ray Inspection of Electronic Assemblies

The JewelBox-70T delivers superior image quality with excellent resolution and sensitivity for laboratory and failure analysis applications. The system’s 10-micron MicroTech™ x-ray source provides magnification from 7X to 2000X, with resolution of 100 line pairs/mm.

Ultra-Compact™

Compact, Desktop Version of the JewelBox

Glenbrook Technologies redefines X-ray Inspection with our smallest JewelBox Micro focus x-ray system yet. With dimensions of just 22”W x 26”L, it’s small enough to fit on a standard desk, in an office or small lab. But it’s big in capabilities with >500x magnification ,5 axis manipulator and advanced image processing.

The World’s First BGA X-ray Reflow Movie

This video was captured using technologies developed by Glenbrook Technologies and described in patent numbers: 6,009,145 and 7,426,258. The video. . .

Exposing BGA: Increase Yields with X-ray Inspection

By Gilbert Zweig The incorporation of BGA packages into electronics assembly has made inspection issues of these leadless components a. . .

How Assemblers Use X-Ray Inspection for BGA

By Steven A. Zweig Ball grid array package handling has it own set of problems and requirements. In replies from. . .