Counterfeit Electronic Component Inspection

RTX-113HV (3500 Series)

Smaller Focal Spot for High Resolution Requirements such as Small Hole Drilling, Micro BGA and QFN Inspection

Ideal for inspection of multi-layer and assembled PC boards. Whether in your drill room for inspecting multilayer PCBs or your SMT Production Floor for inspecting assembled boards, the RTX-113HV (3500 Series) is a user friendly, high performance x-ray machine with unsurpassed reliability.

Ultra-Compact™

Compact, Desktop Version of the JewelBox

Glenbrook Technologies redefines X-ray Inspection with our smallest JewelBox Micro focus x-ray system yet. With dimensions of just 22”W x 26”L, it’s small enough to fit on a standard desk, in an office or small lab. But it’s big in capabilities with >500x magnification ,5 axis manipulator and advanced image processing.

JewelBox-70T™

High Magnification X-ray Inspection of Electronic Assemblies

The JewelBox-70T delivers superior image quality with excellent resolution and sensitivity for laboratory and failure analysis applications. The system’s 10-micron MicroTech™ x-ray source provides magnification from 7X to 2000X, with resolution of 100 line pairs/mm.

Reel-to-Reel Option

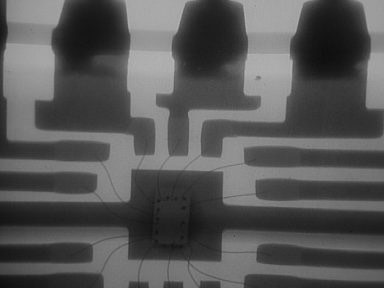

Automated Component Authenticity Inspection

The reel to reel module can be added to any Glenbrook system. This includes the GTI-4000 image processing software. The system will automatically inspect each component on the reel and compare to your know good part. It will check for consistency in lead frames, die size and wire bonds. Any part outside the tolerance will be identified and all images will be saved.

Reel to reel video demonstrating how counterfeit components are detected.

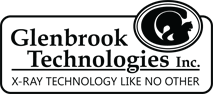

Counterfeit Components

The ever increasing problem of counterfeit components has resulted in problems for thousands of component distributors in controlling the quality of the product. While some problems are detected more easily using visual inspection, there are many issues where only x-ray inspection is more effective.

When would component x-ray inspection be more effective?

This would include checking for the presence of die, cracks in the epoxy, checking wire bonds and product or manufacturing markings that are x-ray detectable.

Since the components generally arrive in reels, trays, tubes and bags, x-ray inspection is ideal since the parts do not need to be removed from packaging. You can x-ray directly through the antistatic bags preserving the quality of the part.

Glenbrook Technologies has affordable, high-resolution x-ray systems that can be used for these requirements.

Now your customer can have the security of knowing that their component distributor is using the necessary quality control procedures to ensure they are getting the actual parts and not counterfeit components.