Latest News & Events

March 1, 2010

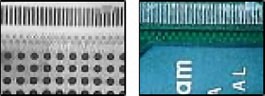

Glenbrook’s NEW Dual-VU™ – View Simultaneous Real-Time X-Ray and Optical Imaging of Electronic and Medical Components

March 2010

Glenbrook Technologies introduces The Dual-VU system providing simultaneous and corresponding magnified real-time x-ray and optical imaging of electronic and medical components. This unique patented* development provides a quality control and component authentication capability never before realized.

The Dual-VU system employs Glenbrook’s patented “Magnification Fluoroscopy” x-ray camera technology, unsurpassed in providing x-ray image detail at low radiation levels, insuring operator safety.

APPLICATIONS |

|

|

|

| BGAs: In a single pass, Glenbrook’s Dual-VU reveals both hidden faults (missing or mis- registered balls and solder bridges or voids) and problems that require visual inspection (such as potato chipping). |

Leaded IC Components: Lifted leads, solder joint integrity and placement accuracy may all be verified simultaneously with the Dual-VU. |

|

|

| Multi-Layer Boards: In the failure analysis lab, Dual-VU makes it possible to visually identify and track a signal trace, which cannot be done with conventional x-ray techniques. |

Multi-Wire, Multi-Layer: The Dual-VU enables users of this technology to confirm electrical continuity of the plating after drilling. |

How It Works |

|

|

This new system combines two of Glenbrook’s patented* developments.First, the MXRA real-time x-ray camera provides high-resolution zoom capability, with a magnification range of 4 to 40 times without the need to reposition the device being inspected.This unique ability to perform as an “x-ray microscope” allows the second innovation — the addition of a vision camera to simultaneously view the inspected device along the same axis. The vision capability is made possible by the use of a special dichroic mirror, transparent to x-rays but polished to a precision optical finish for a sharp vision image.The result is a unique system that provides dual and simultaneous images, even at varying magnifications.*Patent Numbers: 7,426,258 and 5 590 170 |